Production

Ghirardelli S.r.l. a Point of Reference in the Mechanical Sector of Carpentry

Main Processing

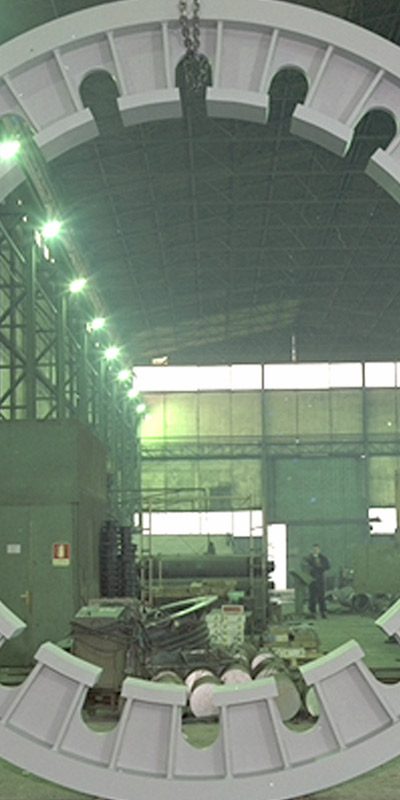

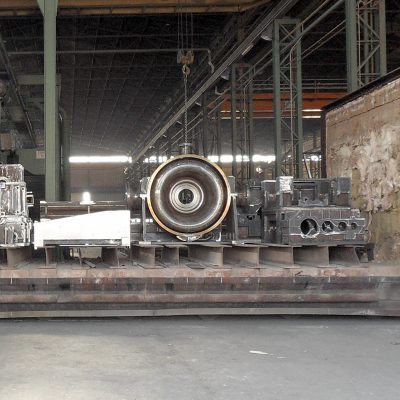

Blank heavy metal structures

Finished mechanical parts

Metal plant and production machinery

Furnaces and galvanisation tanks

Plant and machinery for metal working

Walking beam, vie a rulli, lunettatrici, pinch roll

Production lines and automated equipment

Special welding - X-R, U.T., X-M

Special welding of alloy steels

I.I.S., Lloyd’s Register, R.I.N.A. and AIB-VINÇOTTE approvals

The constant quest for quality, continually upgraded production methods and a fully qualified staff have brought GHIRARDELLI S.r.l. renown in the metal working sector. We also carry out sub-contracted work, such as stress-relieving and sanding of medium-to-heavy items.

Machinery

2 Cranes 15 ton

2 Cranes 12 ton

2 Cranes 06 ton

1 Cranes 5 ton

2 Forklift 3 ton

8 Continuous Wire Welding machines 550 A

2 TIG welding machines 250 A max

2 Electrode Welding machines 400 A max

1 Heating Furnace For Welding Flux 400°C

1 Heating Furnace For Electrode 400°C

2 LINCOLN Submerged Welding Systems

2 Rotating Table Positioners (6000 kg)

1 Rotating Table For Welding (30 ton)

2 Roller Positioners (6000 kg)

2 Band Saw Machines (d. max 350 mm)

1 Horizontal Lathe (d. 250x2000)

1 Automatic Sandblasting Machine 2500x3000x12000 (30 ton)

1 Weighing System For Truck (80 ton)

3 Covered Work Areas mt. 15 x 85 h 8 mt to the crane hook

1 Furnace For Stress Relieving Carpentry mt. 4 x 8 x h 2.8

1 Painting Department Mq. 300

1 Stainless Steel Processing Department Mq. 360

Some Examples of our Realizations

Tel.: +39 030 7450261

Via Lucerna, 6 - 25030 Adro (Bs)

info@ghirardellisrl.it